What Does Work in Process Mean?

Work in process refers to items in a manufacturing plant that are in the stages between raw materials and finished goods (or inventory). In-process goods are expected to be finished and moved into inventory soon, but they aren’t quite complete yet.

Work in Process vs. Work in Progress

Work in process typically refers to short-term assets, while work in progress refers to long-term assets. The difference between the two is time to completion. Often, construction projects are considered work in progress while goods manufacturing is work in process. Again, the key difference between the terms is time to completion.

Example of Work in Process vs. Work in Progress

Work in Process: A Cardboard Box Manufacturer

Consider a cardboard box manufacturer. The company takes sheets of cardboard and runs them through a machine that cuts them to the proper size, perforates sections to make them easier to fold, then folds and glues the boxes into the finished shape. The factory produces thousands of boxes every day.

The box factory contains works in process which will be finished in the short term.

The cardboard box factory lists the following on their balance sheet as work in process:

Raw materials: cardboard and glue.

Inventory: cardboard boxes

Work in process: cardboard that’s been cut and perforated, but not yet folded and glued.

Work in Progress: A Modular Home Builder

Next door to the cardboard box factory is a company that makes modular homes. These are new homes that are built out of sections made in factories. Customers purchase land then choose their desired house style from a seller of house models. That company orders from a factory that ships a prefabricated kit to the building site (where a local builder erects the house).

The modular home builder’s factory contains works in progress that will be finished over a longer period of time.

The modular home builder lists the following on the company’s balance sheet:

Raw materials: steel beams to frame the home, wallboard and sheetrock, rolls of fiberglass insulation, roof shingles, doors and door frames, windows and window frames, vinyl siding, kitchen counters, kitchen sink, bathroom fixtures, light fixtures, door and window hardware, nails, and screws.

Inventory: Completed houses ready to ship when orders come in.

Work in progress: House kits that are partially complete but missing walls, roofs, or floors.

How to Find Work in Process on a Balance Sheet

Work in process is a component of inventory, a current asset. Other components of inventory are raw material and finished goods. Most companies list work in process clearly on the balance sheet. Look down the left side of the balance sheet: WIP is usually listed with raw materials and finished goods, above the subtotal for total inventory.

Is Work in Process an Asset?

Yes, work in process is an asset. It’s reported on a company’s balance sheet along with raw materials inventory and finished goods as a current asset.

How to Calculate Work in Process

Most companies conduct a physical inventory of their plants at the end of a time period (e.g monthly, quarterly, yearly) to calculate the value of their raw materials, work in process goods, and finished goods (inventory). There is also a formula which can be used to estimate WIP.

Work in Process Formula

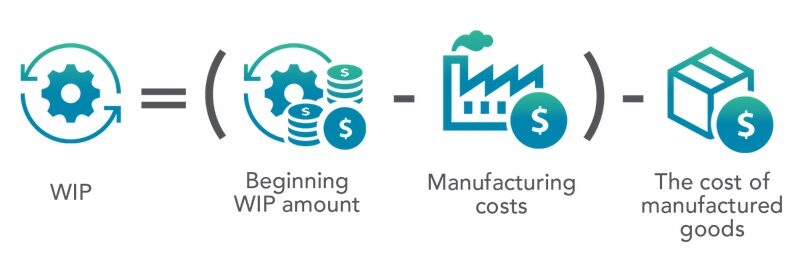

The work in process formula is:

The formula for WIP yields a slightly inexact result. It doesn’t account for manufactured goods pulled from inventory due to damages/defects or manufacturing costs such as scrap and waste. The slight difference between the calculation and the exact value is simply disregarded.

Let’s assume the boxmaker has a beginning work in process amount of $8,000. The company’s manufacturing costs are $220,000 and the cost of manufactured goods is $210,000. The WIP formula looks like this:

WIP = ($8,000 + $220,000) - $210,000

WIP = $228,000 - $210,000

WIP + $18,000

Why Is Work in Process Important?

The work in process number can be an indicator of demand for a product, growth in a marketplace, or changes in capacity. If every manufacturer showed an increase in the WIP amount on their combined balance sheets, industry watchers might assume that there’s a greater demand for their product Or, it could indicate that a manufacturer has improved or expanded its process (e.g. added an assembly line) and may have more goods in process.

Economists and others might watch several industry sectors and make educated guesses about the health of the economy. For example, if they see indicators such as increased WIP in box manufacturers, higher consumer spending overall, and increased shipping volumes, they may infer that more consumer spending is ahead. Such economic indicators are the sum of multiple sectors that paint an overall picture of how the economy is faring.

An increase in WIP may also be a signal that the company needs a cash infusion to meet growing demand. Since WIP indicates demand, shareholders might watch the WIP numbers to see if the company has plans to obtain additional capital.

And of course, the converse to both of these ideas is true. A downturn in WIP may mean that demand is slowing for a company’s products.